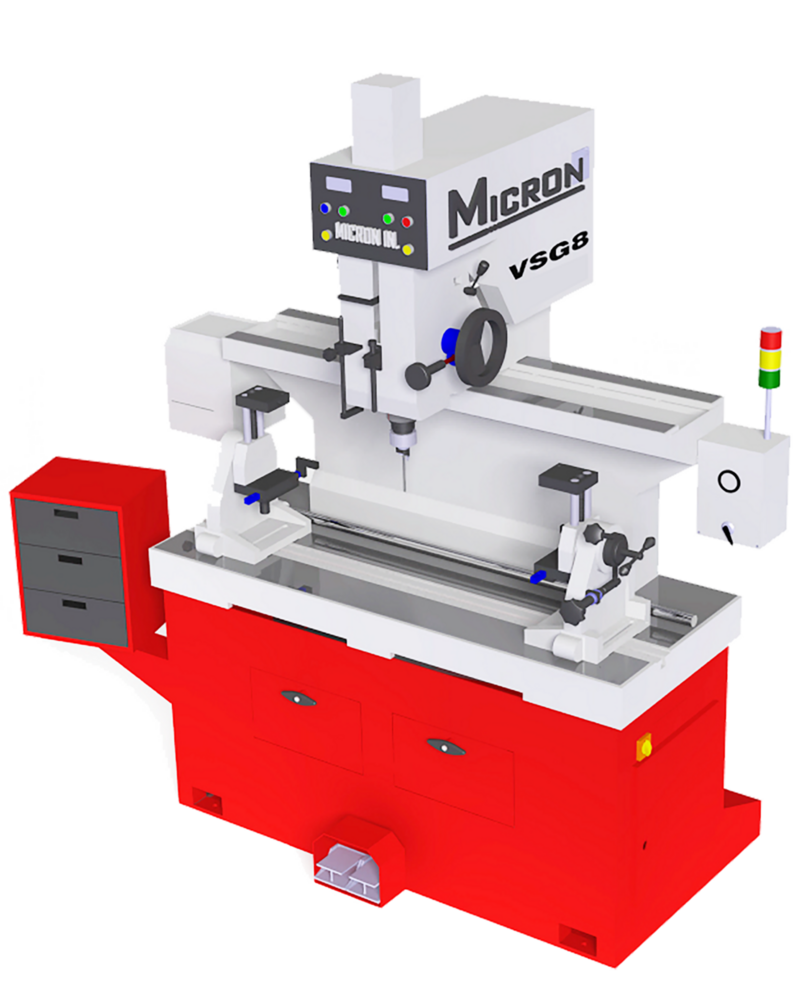

VSG8 Valve Seat Cutting Machine

MOQ : 1 Piece

VSG8 Valve Seat Cutting Machine Specification

- Drive Motor

- Electric Motor 1.5 HP

- Product Type

- VSG8 Valve Seat Cutting Machine

- General Use

- Workshop/Automotive Cylinder Head Valve Seat Cutting

- Material

- Alloy Steel Body

- Type

- Bench/Pedestal Machine

- Capacity

- Covers complete range of automotive cylinder heads

- Weight (kg)

- Approximately 250 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- Cutting Speed

- 50-400 rpm (Adjustable)

- Cutting Thickness

- Up to 12 mm

- Cutting Function

- Valve seat cutting and finishing

- Cooling System

- Integrated Cooling (Water-based)

- Drive Type

- Electric

- Voltage

- 220V / 50Hz

- Dimension (L*W*H)

- 900 x 700 x 1600 mm

- Feature

- Precision Cutting, Easy Operation, Heavy-duty Construction

- Color

- Red

- Warranty

- 1 Years

- Motor

- 1.5 HP Single Phase

- Mechanical Precision

- 0.02 mm

- Cutting Method

- Rotary Multi-insert Cutting Head

- Control System

- Manual Control

- Cutting Material

- Cast Iron, Aluminum, Steel Cylinder Heads

- Cutting Area

- Car Passenger Car Tempo Trucks Heavy Trucks Engine Cylinder Head Valve Seat Cutting

- Safety Features

- Overload Protection, Emergency Stop

- Spindle Taper

- ISO 40

- Lubrication

- Centralized Lubrication System

- Work Head Tilting

- 0-15°

- Maximum Valve Seat Diameter

- 120 mm

- Spindle Travel

- 110 mm

- Clamping System

- Adjustable Quick-Action

- Operation

- Hand and Foot Pedal

- Power Consumption

- 2 kW

- Minimum Valve Seat Diameter

- 16 mm

- Noise Level

- < 75 dB

VSG8 Valve Seat Cutting Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 15 Days

- Packaging Details

- wOODEN cRATE BoX

- Main Domestic Market

- All India

- Certifications

- ISO 9001:2015

About VSG8 Valve Seat Cutting Machine

|

Main Feature : VSG8

|

Heavy-Duty Precision for Automotive Workshops

Engineered for versatility, the VSG8 Valve Seat Cutting Machine delivers outstanding precision cutting with 0.02 mm mechanical tolerance. Its rugged alloy steel body ensures stability during operation, while the variable spindle speed and quick-action clamping substantially boost productivity in demanding workshop settings. From cast iron to aluminum and steel heads, it seamlessly adapts to diverse automotive requirements.

User-Friendly Operation and Safety Innovations

The VSG8 emphasizes ease of use with intuitive manual controls, dual operation (hand and foot pedal), and an ergonomic design. Operators benefit from centralized lubrication and an integrated water-based cooling system, ensuring long-lasting performance and reduced maintenance needs. Overload protection and emergency stop features provide necessary safety assurance for daily operations.

Versatile Application Range and Capacity

Covering a full spectrum of automotive cylinder heads, the VSG8 handles seat diameters between 16 and 120 mm with cutting capacities up to 12 mm thickness. Its tilting work head offers precise angle settings, making the machine suitable for various engine typespassenger cars, tempos, and heavy-duty trucks. The compact footprint ensures it fits into most workshop environments.

FAQs of VSG8 Valve Seat Cutting Machine:

Q: How is the VSG8 Valve Seat Cutting Machine operated?

A: The VSG8 is controlled manually and supports two methods of operationhand lever and foot pedalallowing for user-friendly and ergonomic use in diverse workshop scenarios.Q: What types of cylinder heads can this machine process?

A: This machine covers the entire range of automotive cylinder heads, including those from passenger cars, tempos, and heavy-duty truck engines. It is compatible with cast iron, aluminum, and steel cylinder heads.Q: Where is the VSG8 ideally used?

A: The machine is best suited for workshops specializing in automotive cylinder head repairs, rebuilds, and valve seat machining. Its sturdy construction and versatile capabilities make it a valuable asset in professional engine reconditioning settings.Q: What is the process for cutting and finishing valve seats using the VSG8?

A: The operator positions the workpiece using the adjustable quick-action clamping system, sets the spindle speed (50-400 rpm), tilts the work head as required, and uses the rotary multi-insert cutting head to cut and finish the valve seat. Centralized lubrication and cooling ensure smooth, precise cuts.Q: When should the machines lubrication and cooling systems be checked?

A: Regular checks of the centralized lubrication and integrated water-based cooling system should be carried out according to your daily or weekly maintenance schedule to ensure optimal performance and component longevity.Q: What are the main benefits of using the VSG8 in automotive workshops?

A: Benefits include precision machining (0.02 mm tolerance), easy and safe operation, adaptability to various cylinder head types, efficient cooling, and heavy-duty construction for long-term durability. Enhanced safety features like overload protection and emergency stop further secure the working environment.Q: What warranty and after-sales support does the VSG8 offer?

A: The machine comes with a 1-year warranty, providing confidence in its quality and ensuring support for repairs or parts replacement within the warranty period.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Valve Seat Cutting Machine Category

VGS7A Valve Seat Cutting Machine

Price 9999 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Color : Red

Material : Steel

Voltage : 220415 Volt (v)

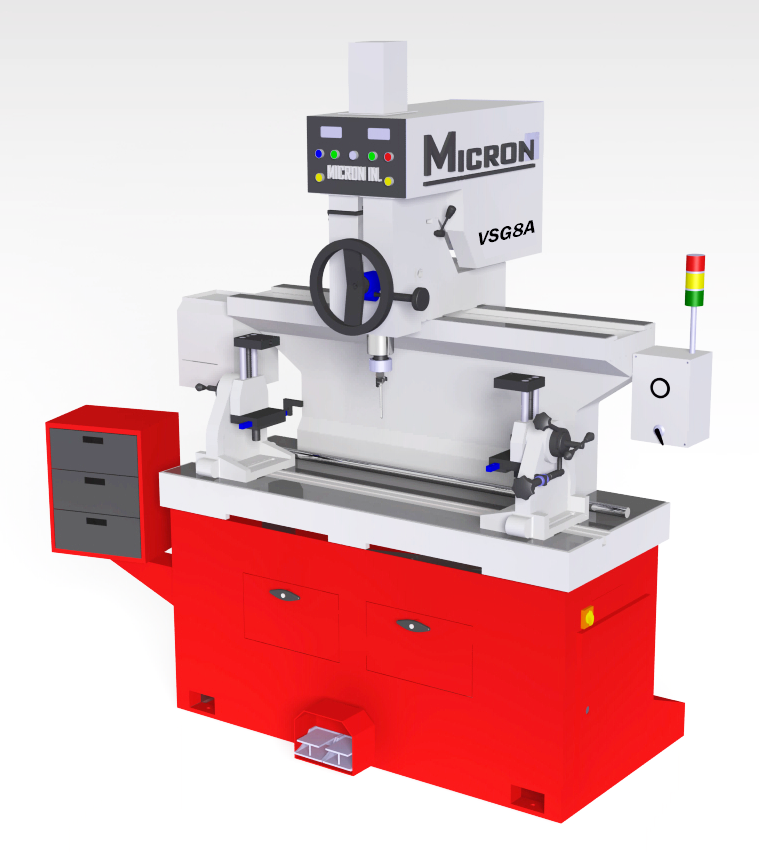

VSG8A Valve Seat Cutting Machine

Price 9999 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Color : Red

Material : Steel

Voltage : 220415 Volt (v)

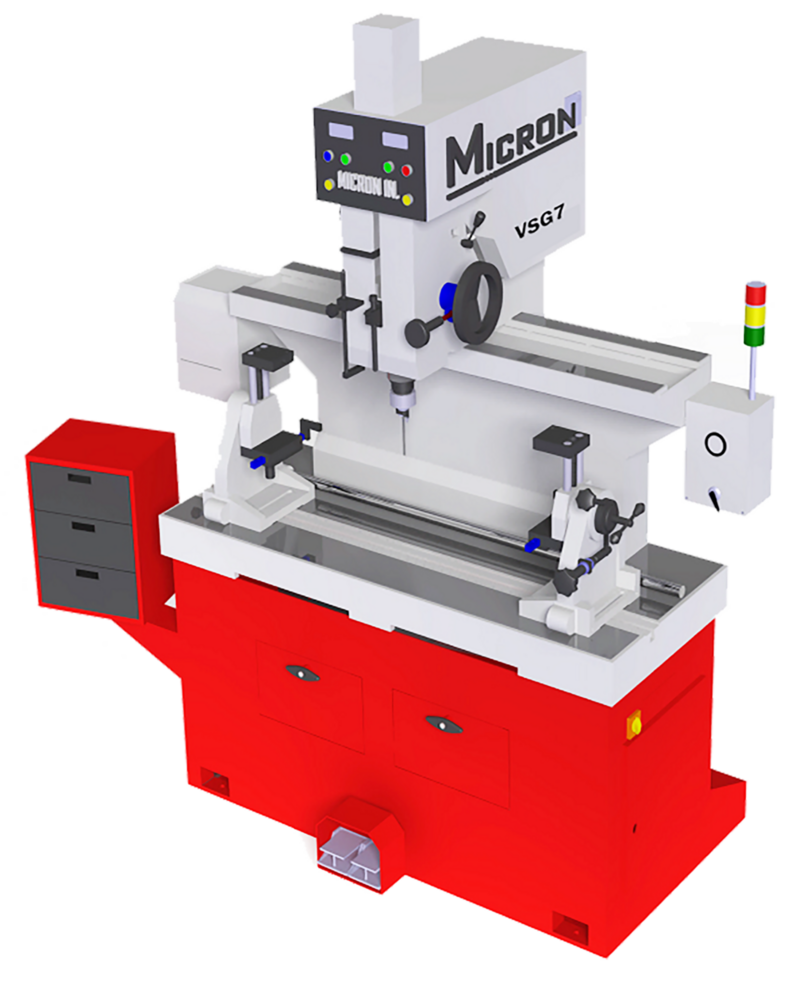

VSG7 Valve Seat Cutting Machine

Price 9999 INR / Unit

Minimum Order Quantity : 1 Unit

Warranty : 1 Year

Color : Red

Material : Steel

Voltage : 220415 Volt (v)

VSG5 Valve Seat Cutting Machine

Price 9999 INR / Unit

Minimum Order Quantity : 1 Piece

Warranty : 1 Years

Color : Red

Material : Steel

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese