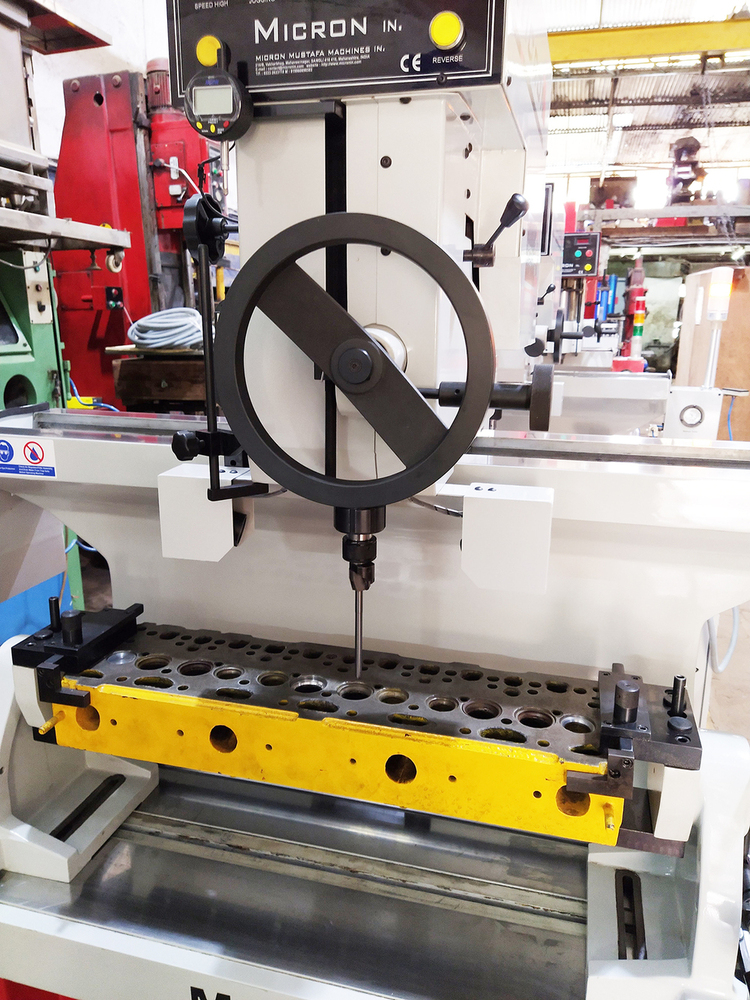

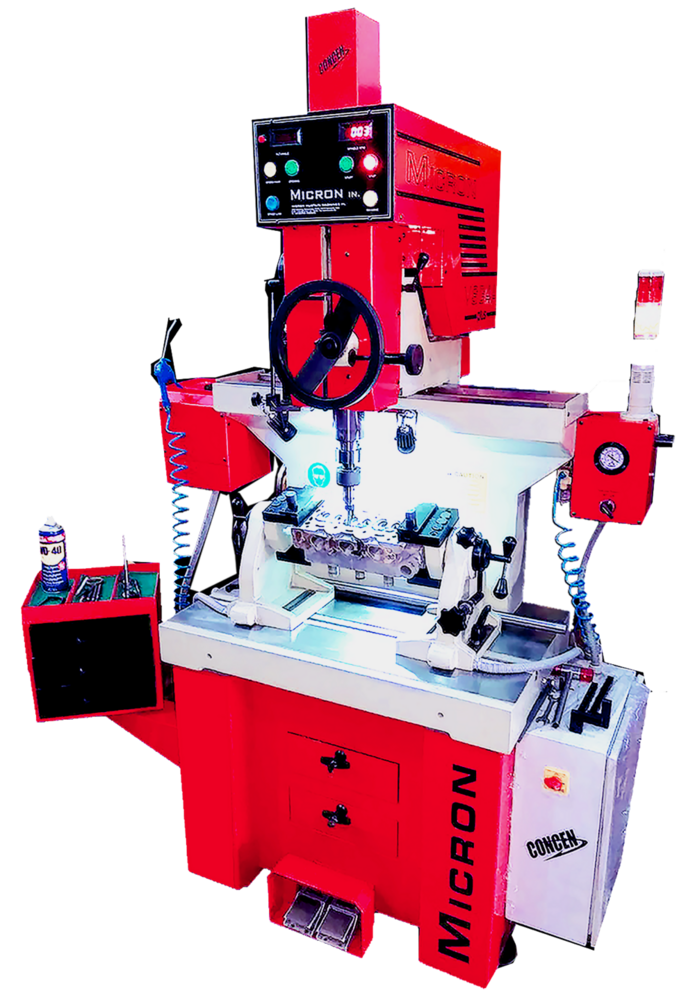

VSG7X Valve Seat Guide Machine

Price 9999 INR/ Unit

VSG7X Valve Seat Guide Machine Specification

- General Use

- Industrial

- Material

- Steel

- Computerized

- No

- Automatic

- Yes

- Drive Type

- Electric

- Voltage

- 220-415 Volt (v)

- Feature

- Environmental Friendly, Good Quality

- Color

- Red

- Warranty

- 1 Year

VSG7X Valve Seat Guide Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- Nahva Sheva

- Supply Ability

- 100 Units Per Year

- Delivery Time

- 30 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

- Main Domestic Market

- All India

About VSG7X Valve Seat Guide Machine

Main Feature VSG7X

1 The Micron VSG7X uses the proven fixedcarbide pilot tooling with front mount steering

wheel forspindle downfeed The machine has two modes of operation Front Wheel for Rapid

control feed and Side Knob wheel for Precise FineFeed

2 VSG7X Spindle powered by2Hp 15kW High Torque AC Spindle Motor

FrequencyInvertor to control spindle torque throughout the speed range 600 Rpm Thiscontrol

Givesmaximum torque at all speeds resulting in fine surface finish even with thehardest valve

seats Found in todays CNG Engines

3 VSG7X Spherical Centering System WithSolenoid Locking Power Head And Work

head Air Floats Independently in 3axis toinsure Fast And Accurate Guide Centering

4 Micron VSG7X machines are manufactured fromheavy thick wall cast iron The all cast iron

Rigid platform is precision machinedproviding superior Accuracy as compared to fabricated

steel Rigidity is vital in producingOptimum Accurate chatter free valve seat cutting

All Cast Parts Are Flame Hardened andStress Relived which Will lead to Repeated Accuracy

and Long Last

5 Three angle single blades insert cuts allthree angles at once and produce accurate finished seat

with finer Ra Value surface with Leakproof sealing between Valve And valve seat They assure

exact seat width from head to head plusconcentricity between seat and guide

6Spindle Head Tilts to 15 degree on both Sides to accommodate any GuideAxis For

Machining of All New Generation Importedand Indian Cylinder Head

7 AdvanceDesign of Spindle Adopter Assembly mechanism reduced time to completejob with less runout and Better Concentricity

8 Takes Minimum Floor Space to Handle theComplete Range Of Heavy Automotive and Industrial

CylinderHeads

9Dial In Variable Spindle Speed 30 to 600 Rpm Without Stopping theRotation

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Valve Seat Guide Machine Category

VSG7Plus Valve Seat Guide Machine

Price 9999 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Voltage : 220415 Volt (v)

Drive Type : Electric

Warranty : 1 Year

VSG8Plus Valve Seat Guide Machine

Price 9999 INR / Unit

Minimum Order Quantity : 1 Piece

Material : Steel

Voltage : 230415 Volt (v)

Drive Type : Electric

Warranty : 1 Years

VSG8X Valve Guide Machine

Price 9999 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Steel

Voltage : 220 Volt (v)

Drive Type : Electric

Warranty : 1 Years

VSG5SPlus Valve Seat Guide Machine

Price 9999 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Steel

Voltage : 440 Volt (v)

Drive Type : Electric

Warranty : 1 Year

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese